Studies on seemingly frivolous soap-bubble arrays carried out by Dr. Yoel Stavans of the Department of Electronics are shedding light on the properties of a wide range of systems with cellular structures. They include magnetic recording films, silicon wafers, ceramics, foams and polycrystalline metals and alloys.

When a thin film of liqueified metal is deposited on a flat surface and cooled, a solid coating with polygonal regions is formed, a pattern very similar to that present in soap-bubble arrays. Moreover, the average size of these regions also expands with time in a manner resembling the growth of soap-bubble arrays. Since control of this growth is instrumental in determining the properties of cellular-structured materials -- namely the strength of alloys, the electronic noise in integrated circuit chips and the mechanical resilience of foams -- the study of soap-bubble arrays is of major technological relevance.

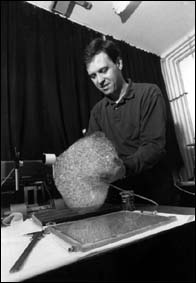

Surprisingly, an ordinary photocopying machine is virtually the only equipment used in Dr. Stavan's experiments. He puts an array of colored soap bubbles in a shallow transparent tray, which is covered in such a way that the bubble film stretches between flat upper and lower surfaces, attaining a uniform height. Liquid collects at the lower boundaries between contiguous bubbles, so that the evolution of the bubble array can be followed by photocopying at convenient intervals.

As reported in a recent issue of Nature, Dr. Stavans has shown that bubble arrays evolve in two stages: a transient stage whose evolution depends on initial conditions, and a long-term stage whose statistical properties, such as area and number of sides, are independent of initial conditions. These same statistical properties have also been found in other cellular systems, despite their different mechanisms of growth and evolution.